Laser Cutting and Engraving Wood: Precision & Creativity - Guangdong Gumo Crafts Technology Co., Ltd.

Core Highlights

Laser cutting offers unmatched precision for intricate wood designs

Reduces material waste and speeds up production efficiency

Versatile applications from personalized gifts to custom signage

Environmentally friendly process with minimal chemical usage

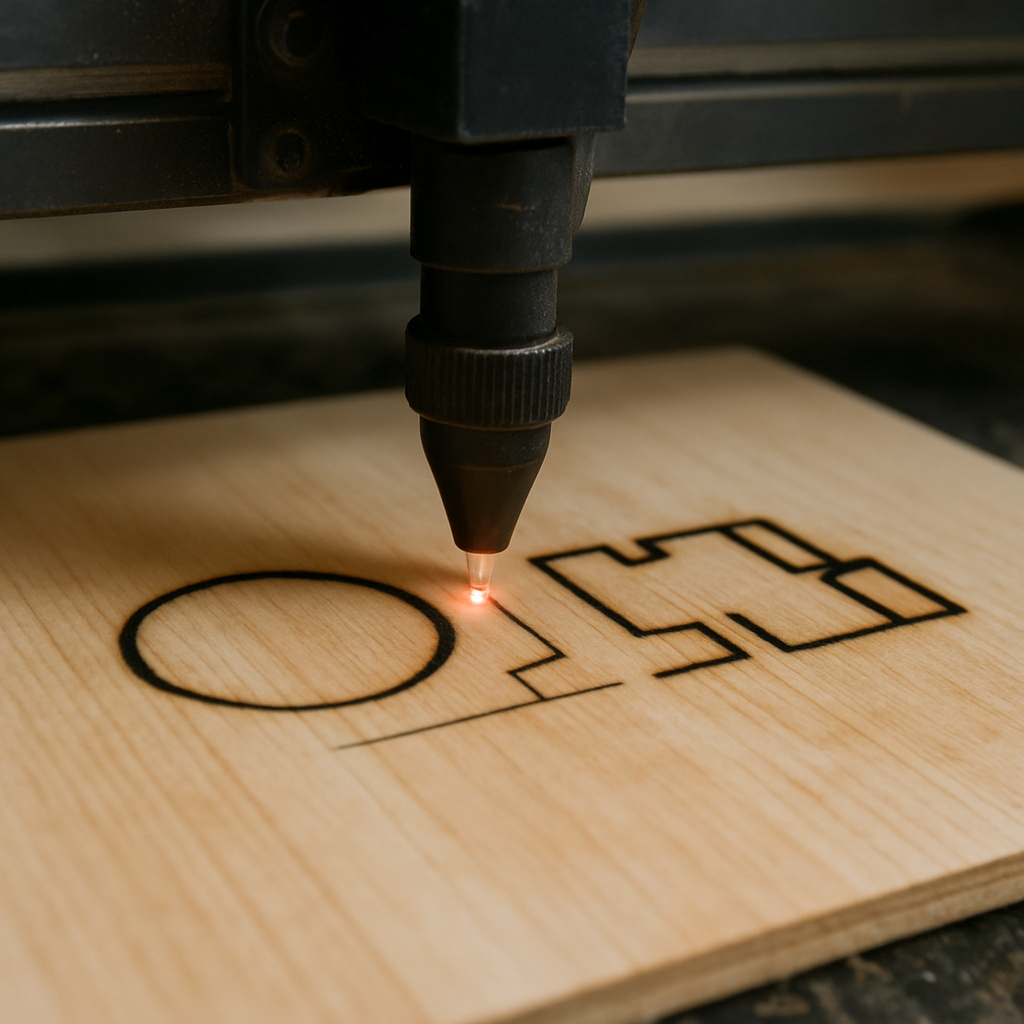

Laser cutting and engraving wood is a game-changer in modern woodworking. This technology offers precision and creativity that traditional methods can't match. With a focused laser beam, intricate designs become possible on various wood types. The process is efficient, reducing waste and speeding up production. 3D wooden puzzles products are popular in many industries, from personalized gifts to custom signage. The versatility of wood laser machines allows for both cutting and engraving, expanding design possibilities.

Whether you're a hobbyist or a professional, laser technology opens new doors in woodwork engraving. Discover how this innovative approach can transform your projects and inspire creativity.

What Is Laser Cutting and Engraving Wood?

Laser cutting and engraving involve using a laser beam to cut or mark wood surfaces. The laser precisely targets areas, creating detailed designs and patterns.

Different types of wood, including hardwood, softwood, and plywood, can be used. The technology allows for intricate woodwork engraving, enhancing the final product's aesthetic appeal.

Here's how the process works:

A laser focuses on the wood surface.

The heat cuts or engraves the material.

Complex patterns and textures are achieved.

This non-contact method minimizes damage to the wood. The precision afforded by the laser creates clean edges and tight tolerances, which are perfect for detailed work.

Key Advantages of Laser Cutting and Engraving Wood

Laser cutting wood presents a host of advantages. It excels in offering precision that traditional tools struggle to achieve. This precision allows craftsmen to produce intricate and complex designs effortlessly.

Efficiency is another benefit of laser technology. It reduces material waste, which helps in conserving resources and minimizing costs. Additionally, the process speeds up production time.

Laser cutting is versatile, accommodating various wood types. From hardwoods to softwoods, the technology adapts seamlessly, delivering consistently high-quality results across the board.

The technology also supports mass production with repeatable outcomes. This makes it ideal for businesses focusing on scale and quality.

Some additional advantages include:

Reduced need for post-processing.

Minimal risk of damaging the wood.

Environmentally friendly process with fewer chemicals.

Finally, laser engraved wood products are durable. They withstand the wear and tear of time, making them long-lasting and valuable.

Popular Applications for Lasered Wood

Lasered wood has found diverse applications in various fields. Personalized gifts are a popular choice, where custom messages and names are engraved on wood items. This creates meaningful and unique products.

Home décor is another area that benefits from laser technology. It allows for the creation of intricate wall art and custom furniture pieces that enhance living spaces. The ability to tailor designs to customer specifications adds immense value.

Incorporating logos and branding on wood is also common. Businesses utilize this for signage and promotional products, helping to maintain brand identity in a stylish way.

Some popular applications include:

Custom signage and decor

Personalized gifts like wooden owl clock puzzles

Branded promotional products

Educational tools and models made from wood are enhanced by laser cutting technology. Detailed engravings help create engaging and informative materials.

Finally, the art world has embraced lasered wood for its ability to reproduce intricate patterns. Artists are continuously exploring new creative possibilities offered by wood laser technology.

Comparing Laser Cutting to Traditional Woodwork Engraving

Laser cutting offers precision and speed, which are major advantages over traditional methods. Traditional tools often struggle with intricate designs, whereas lasers excel in this area.

Furthermore, laser technology minimizes material waste. This efficiency saves time and reduces costs for businesses and hobbyists alike. In contrast, traditional methods frequently require more material and generate more waste.

Some key differences include:

Precision of laser cuts versus manual tools

Reduced material waste with laser technology

Speed and efficiency improvements

Laser methods also reduce the risk of damaging the wood. Traditional tools can cause splitting or chipping during the process. Thus, many find laser cutting and engraving to be a superior choice for detailed and consistent woodwork results.

Choosing the Right Wood Engraving Machine

Selecting the right wood engraving machine is crucial for achieving quality results. Consider the project's size and complexity before making a purchase.

Machines vary in power and size, catering to different needs. Smaller machines suit hobbyists, while larger setups fulfill industrial demands. It's important to choose based on your specific requirements.

Factors to consider include:

Power level and speed

Machine size and workspace

Software compatibility with your design tools

Don't overlook user-friendly features and support options. These aspects can ease the learning process. Finally, choosing a machine with good reviews and a reliable warranty will help ensure a satisfying and efficient woodwork experience.

Tips for Achieving the Best Results with Wood Laser Technology

Maximizing the potential of wood laser technology requires practice and attention to detail. Understanding your machine's settings is the first step toward achieving optimal results.

Here are a few helpful tips:

Adjust laser power and speed according to wood type

Clean the lens regularly to prevent residue build-up

Use well-finished wood for cleaner cuts

Experiment with scrap pieces to perfect your technique. This practice will help adjust settings without risking your main project. Also, ensure a steady airflow to remove smoke and prevent damage. Maintaining your equipment is vital for consistent quality and accuracy in your laser cutting and engraving tasks.

Inspiring Ideas for Laser Engraved Wood Products

Laser engraved wood products offer endless creative possibilities. They combine functionality with artistic flair, suitable for varied occasions and purposes.

Here are some inspiring ideas:

Personalized cutting boards

Custom wooden signs for homes or businesses like custom wooden heart signs

Intricate wooden jewelry

Laser technology can transform ordinary pieces into unique items. You can create personalized gifts or stunning home decor that draws attention. Each piece becomes a reflection of creativity and precision.

Consider incorporating text, images, or intricate designs into your woodwork. This ability to customize can make your products stand out in any market.

Conclusion: The Future of Woodwork Engraving

The future of woodwork engraving lies in laser technology. With its precision and flexibility, it continues to evolve, offering new opportunities for creativity and efficiency.

As more people discover its benefits, laser cutting and engraving will play a larger role in both artistic and practical applications. This technology not only enhances traditional woodworking but also opens doors to innovative designs. Embrace this trend to stay ahead in the craft world.