Effective Strategies to Reduce Lead Time in Wooden Product Export

In the wooden product export industry, lead time—the duration from order placement to delivery—plays a crucial role in customer satisfaction and operational efficiency. Long lead times can result in delayed shipments, higher costs, and lost business opportunities. For exporters like Gumowoodcrafts, optimizing lead time is essential to maintaining a competitive edge. This article explores actionable strategies to streamline processes, improve logistics, and reduce lead time effectively.

Understanding Lead Time in Wooden Product Export

Lead time consists of multiple stages:

-

Order Processing – Time taken to confirm and prepare the order.

-

Production – Duration of manufacturing or customization.

-

Packaging & Quality Control – Preparing goods for shipment.

-

Shipping & Logistics – Transit time to the destination.

Reducing delays at each stage ensures faster delivery and better customer experiences.

Key Strategies to Reduce Lead Time

1. Optimize Production Planning

Efficient production scheduling minimizes bottlenecks. Consider:

-

Batch Processing – Group similar orders to reduce setup time.

-

Lean Manufacturing – Eliminate waste in workflows (e.g., excess inventory, overproduction).

-

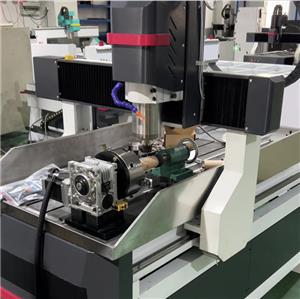

Advanced Machinery – Invest in automated tools for faster processing.

2. Strengthen Supplier Relationships

Delays in raw material procurement extend lead times. Solutions include:

-

Local Sourcing – Work with nearby suppliers to shorten delivery cycles.

-

Long-Term Contracts – Secure reliable suppliers with negotiated lead times.

-

Buffer Stock – Maintain strategic reserves of high-demand materials.

3. Improve Logistics & Shipping

Shipping delays are a major contributor to long lead times. Optimize by:

-

Choosing Reliable Carriers – Partner with freight forwarders specializing in wooden goods.

-

Consolidated Shipments – Combine orders to reduce transit frequency.

-

Port Selection – Use less congested ports for faster customs clearance.

4. Leverage Technology for Efficiency

Digital tools enhance visibility and coordination:

-

ERP Systems – Track orders, inventory, and shipments in real time.

-

Automated Documentation – Reduce paperwork delays with digital invoicing and bills of lading.

-

GPS Tracking – Monitor shipments to anticipate and resolve delays.

5. Streamline Order Processing

Manual order handling slows operations. Solutions:

-

Online Order Systems – Allow customers to submit orders digitally.

-

Predefined Workflows – Standardize order confirmation and fulfillment steps.

6. Enhance Packaging Efficiency

-

Standardized Packaging – Use uniform sizes to speed up packing.

-

Protective Yet Lightweight Materials – Reduce shipping weight without compromising safety.

Measuring Success: Key Performance Indicators (KPIs)

Track these metrics to evaluate improvements:

-

Average Lead Time – Compare before and after changes.

-

On-Time Delivery Rate – Aim for 95% or higher.

-

Inventory Turnover – Higher turnover indicates efficient production.

-

Wooden Box – Perfect for secure packaging of delicate wooden products.

-

Wooden Game Board – A popular export product with efficient production processes.

Conclusion

Reducing lead time in wooden product export requires a holistic approach—optimizing production, logistics, and supplier coordination. By implementing these strategies, Gumowoodcrafts can achieve faster deliveries, lower costs, and improved customer satisfaction.

For exporters, continuous improvement in lead time management is not just an operational goal but a competitive advantage. Start applying these methods today to enhance efficiency and grow your market reach.

Explore more about our products and news: